Technology

How a biogas plant works

Biogas is produced by the biological decomposition of biomass. In smaller biogas plants, the input usually consists of agricultural substrates such as manure and slurry or feed residues. In larger plants, energy crops (corn, GPS, sugar beets, etc.), lawn clippings, various types of straw such as corn straw, food waste, and food manufacturing waste are also used.

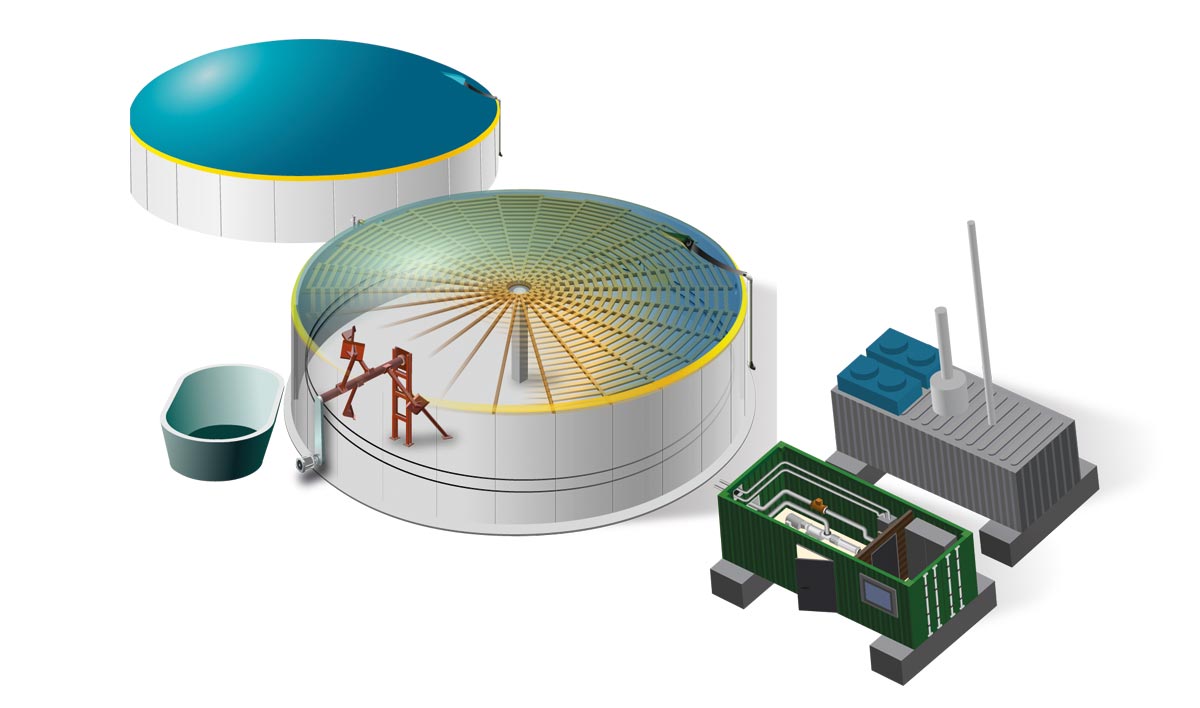

The substrate is fed into the airtight heated fermentation tank, the digester. Agitators in the vessel ensure even distribution of the biomass and prevent sinking and floating layers that could disrupt the gas extraction process and plant function. Fermentation in the digester produces biogas. The biogas process in detail.

The biogas produced is collected by a flexible roof above the digester and then transferred to the CHP plant through piping that incidentally “dries” the gas. The power plant takes over the production of electricity, which naturally also generates heat. Part of this process waste heat is returned to the biogas plant to heat the fermenter. The remainder can be used to heat farm and residential buildings on site or fed into an existing heating network. The energetic input from agricultural by-products is thus optimally utilized; hardly anything is lost. Furthermore, fermentation residues can be reused as high-quality fertilizer. So it’s no wonder that biogas plays an important role in the energy transition. One advantage over other renewable energies is that biogas can be stored and used as needed without having to be converted into another energy source.

The electricity produced with the help of biogas in the CHP unit is fed directly into the public grid, for which the operator of the biogas plant receives remuneration in accordance with the EEG. Alternatively or additionally, the biogas produced can be refined into biomethane for direct feed-in to the public natural gas grid. Biomethane can also be used as a renewable fuel on site.