High-tech for your

OEKOBIT biogas technology is adapted to the site, high-quality, ready-to-use and easy to maintain. OEKOBIT offers substrate-flexible, scalable biogas plant technology for your biogas and biomethane production. Using innovative engineering, field-tested design concepts and perfectly matched components from the digester to the combined heat and power plant, we guarantee the quality, functionality and maximum availability which is typical for OEKOBIT plants and which, in return, ensures the economic success of our clients.

The OEKOBIT design scores with intelligent solutions developed in-house in all plant areas, from gas storage and -distribution, over agitating to heating and upgrading.

OEKOBIT tank concept

With its biogas plants, OEKOBIT relies on prefabricated tanks made from highest concrete quality or steel. The intelligently prefabricated component parts are extremely resistant to chemical reactions. They are supplied true to size, assembled on site and sealed absolutely tight.

OEKOBIT agitator technology

Agitators are used to homogenize the substrates in the fermentation tank. Perfectly coordinated, they prevent floating and sinking layers and encourage fast discharge of gas from the viscous substrate.

OEKOBIT heating concept

Temperature fluctuations of only one degree can disrupt the sensitive biological process in the digester and drastically minimize the gas yields. OEKOBIT keeps the active microbiology at a constant process temperature through a stainless steel heating mounted on the inner wall of the tank.

OEKOBIT gas management

Double membrane roof

The biogas produced in the digester and post-digester is stored temporarily in a so-called gas holder, which serves as both a flexible gas buffer reservoir and desulphurization space. Gas impermeability of the gas holder is absolutely imperative for the safe and profitable operation of the biogas plan

Gas distribution concept

The distribution of the produced biogas to one or more consumers is a factor not to be underestimated when it comes to the functional performance of the overall system.

OEKOBIT meshed synthetic woven

OEKOBIT meshed synthetic woven desulfurized your biogas plant. The result: A much higher gas quality and less operating expense for biochemical filters.

OEKOBIT substrate concept

Dosing and introduction technology

OEKOBIT dosing solutions are extremely rugged and designed for safe, substrate-flexible operation. They use proven technology which is capable of feeding-in various and even difficult substrates in a reliable way.

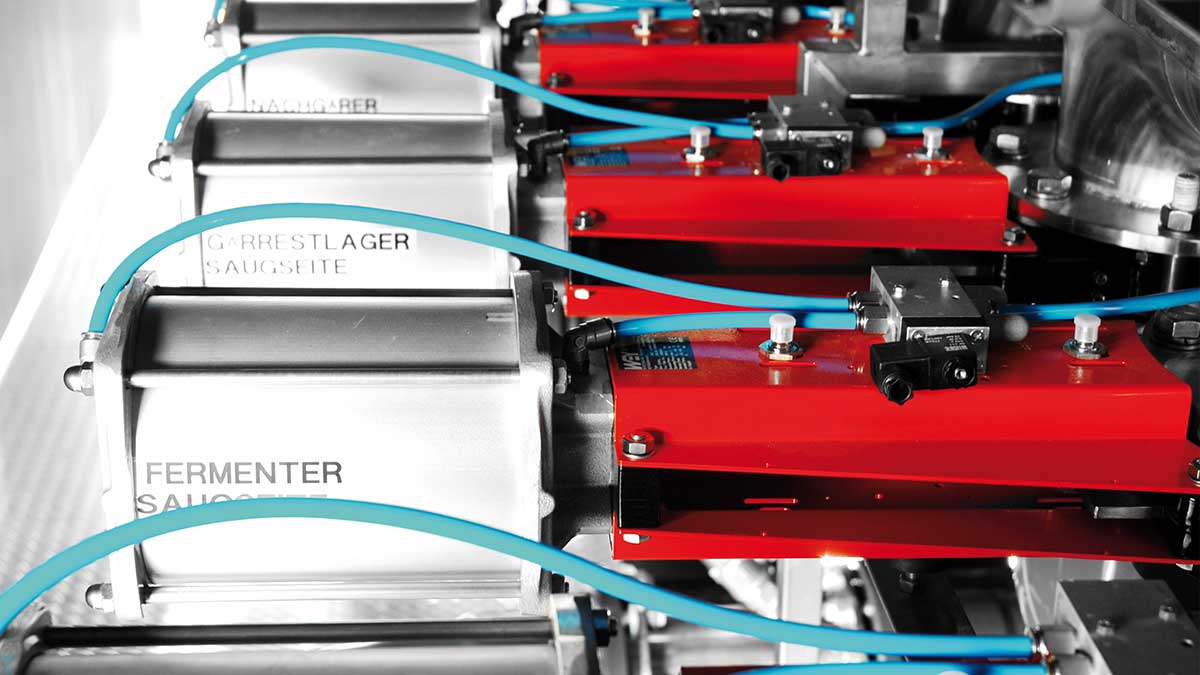

Pump technology

Thanks to the OEKOBIT pump system, there is a free choice of substrate streams, i.e. substrates can be pumped from any tank into any other tank. There is also the option to link all tanks together.

Separation and digestate processing

In large-scale biogas plants, considerable volumes of substrate are moved. Several practical and logistical advantages can be achieved through solid-liquid separation of the digestate.

OEKOBIT upgrading concept

CHP electricity generation

The CHP is generally the most expensive component part of a biogas plant. Therefore, in addition to high efficiency, the unit’s longevity and reliability are decisive factors.

Gas upgrading

Upgrading of biogas opens up additional options for its use and therefore increases the profitability of your biogas plant. The feeding of biogas into the public natural gas network and the use of biogas as a fuel for example, require the upgrading to natural gas quality. OEKOBIT offers plant operators all the common processes for doing so.

OEKOBIT safety concept

Safety has always been a top priority for OEKOBIT. As the first manufacturer of biogas plants, all our plants have been audited by the German Association for Technical Inspection (Technischer Überwachungsverein, TÜV) within a safety-related test procedure.

OEKOBIT Process Control System

The opportunities for increasing biogas production through targeted manipulation within the biogas process are developing rapidly. An intelligent Process Control System for biogas plants is the key to turbocharged profitability. With the Process Control System (PCS) for biogas plants specially developed by OEKOBIT, we actively help operators of biogas plants to optimize efficiency and reduce the plant’s power consumption in order to achieve maximum profitability. Despite the complex demands on automation and measurement technology of the biogas plant, the OEKOBIT Process Control System is intuitive and easy to operate.